Essential oils

Cooling water outlet

Vapours from the still

Practical Action

Cooling water inlet

Condensate out

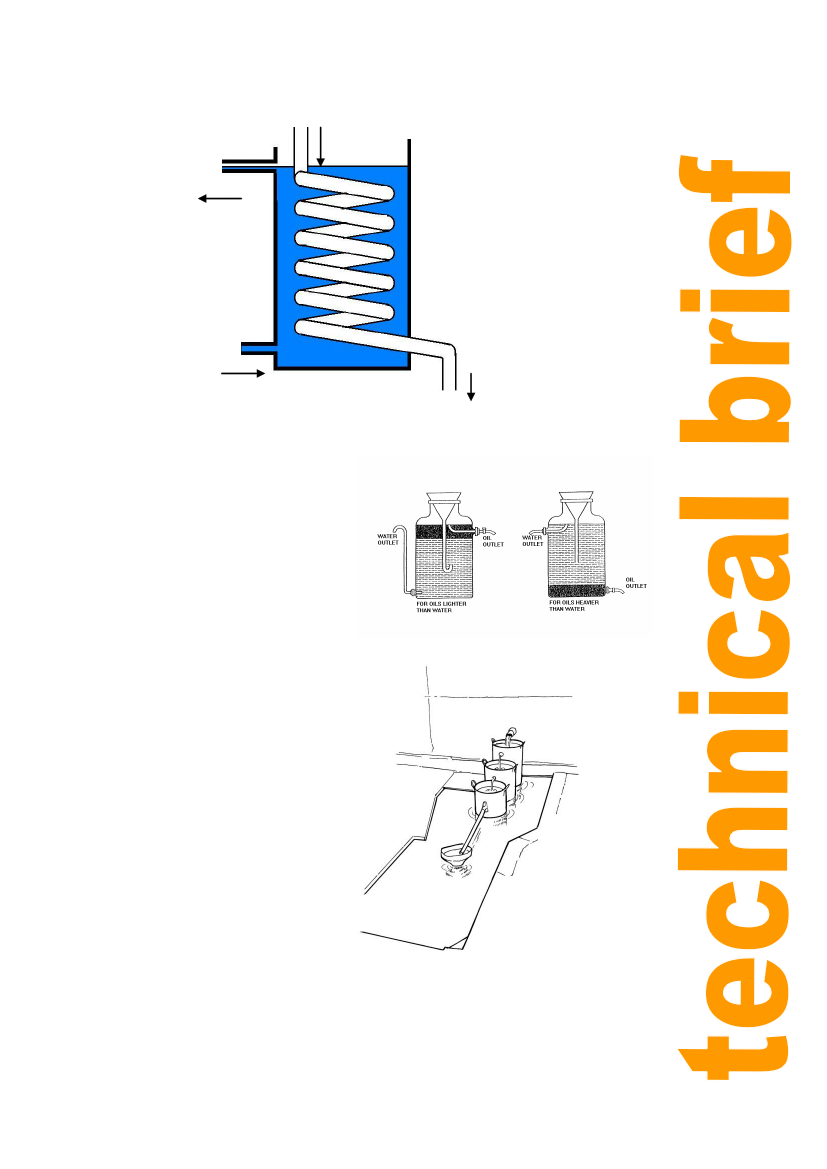

Figure 4: A simple condenser

Oil separation

The final step in the distillation of essential

oils is the separation from the water flowing

from the condenser using a special flask

called a Florentine. This is a very important

stage as small quantities of oils of very high

value are being handled and maximum

efficiency is the key to profitability.

Most essential oils are lighter than water and

float to the surface of the Florentine. Some

oils, however, are denser than water and

sink to the bottom. For this reason two

types of Florentine are used as shown in

Figure 5. It is common practice to link

several Florentines together. Most of the

oil will separate in the first flask but some

will pass over with the water to the second,

third etc. separates the oil from the water.

This is usually done by letting the mixture

settle in a large container made of glass. If

the oil is heavier than water, the oil is

collected from the bottom of the container,

and if lighter from the top.

If the water is cloudy after separation, it

should be returned to the distillation unit

and redistilled. This is called

'cohabitation'.

Figure 5: Florentines used for oil separation

Using a sequence of

oil separators will

extract a greater

amount of oil.

At the end of the distillation the oil and water in the Florentines is placed in a large laboratory

separating funnel (Figure 6) and allowed stand for several hours after which the water can be run

off. At is stage a small plug of cotton wool is often placed in the outlet of the funnel. As the oil

runs through the plug any final traces of water are removed.

5